Cost effective plasma nitriding by using APPN – ADVANCED Pulsed Plasma Nitriding

APPN is an inexpensive and efficient way to enhance the fatigue strenght, Hertzian pressure and the hot hardness of tools. The process represents a most economically efficient processing of tools for molding, die casting, forging, extrusion of aluminum and various precision components. This type of surface thermochemical processing may be precisely controlled, which is necessary for subsequent combination of PVD or PeCVD with coating.

Advantages of plasma nitriding using APPN

- Extremely low operation costs (low consumption of electric energy and gas)

- Flexible and, at the same time, reliable process

- Efficiently controllable metallurgical structure

- Special nirtiding process for PVD coating of forming tools, plastic injection molding and precision components

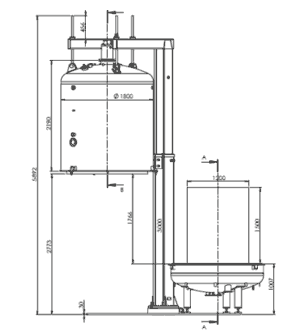

Standard dimensions

Bell furnace APPN 600 x 1000 – 30 kW screen, 30 kW BIAS

Bell furnace APPN 1000 x 1000 - 60 kW screen, 30 kW BIAS

Bell furnace APPN 1200 x 1500 - 90 kW screen, 30 kW BIAS

Customized dimensions may be provided upon request.